PRODUCTS CENTER

Anionic polyacrylamide

- Product Description

-

Product Introduction

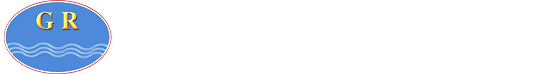

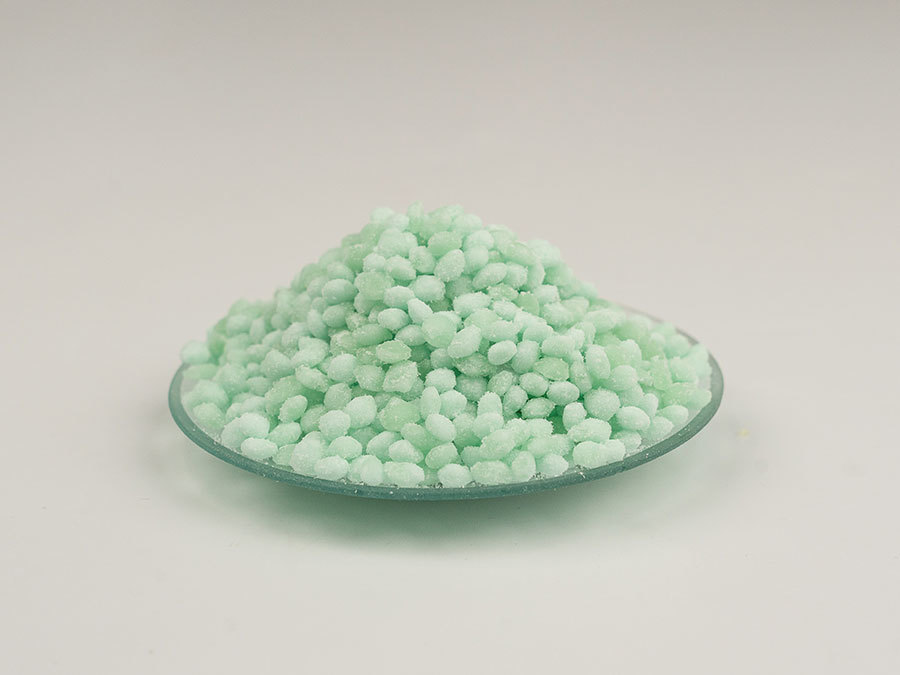

Anionic Polyacrylamide (APAM) appears as white powder granules, with a molecular weight ranging from 3 million to 25 million. It is highly water-soluble, dissolving in water but not in organic solvents. The effective pH range is 6 to 10. In neutral and alkaline media, it exhibits the characteristics of a high-polymer electrolyte, sensitive to salt electrolytes, and can cross-link with high-valence metal ions to form insoluble gels.

Characteristics of High-Viscosity Anionic Polyacrylamide for Incense Making

1. Good solubility, high viscosity, strong toughness, easy to burn with little or no smoke, odorless combustion, non-toxic, etc.;

2. Stable product performance avoids inconsistencies in bonding quality due to differences in origin and time of other plant gum powders and ordinary starch. In incense production, repeated adjustments to the formula are required to prevent product quality instability.

3. Incense products have a smooth and clean appearance, good molding, and are not easily broken;

4. Its cold water gelatinization property eliminates the need for boiling. Materials can be directly mixed evenly, water added and stirred for production. Moreover, the material after mixing with water will not harden and become unusable even after being left for a long time, effectively saving energy and facilitating production operations.

Product Parameters

Anionic Polyacrylamide Technical Index:

CAS Number:

9003-05-8

Product Appearance:

White, free-flowing emulsion

Ion Type:

Anionic

Molecular Weight:

5 million-25 million (adjustable)

Degree of Hydrolysis:

10-45% (adjustable)

Solid Content:

≥98%

Water-insoluble matter:

≤0.02%

Dissolution Time:

≤3 minutes

Preparation Concentration:

0.1% (usually)-0.5% (maximum)

Storage Time:

Product (6 months), prepared solution (3-15 days)

Residual Units:

≤0.1%

Product Applications:

For industrial use only

Applications of Anionic Polyacrylamide (APAM) in Water Treatment

1. Industrial wastewater treatment: For suspended particles, high concentration, positively charged particles, wastewater with neutral or alkaline pH, wastewater from steel plants, electroplating plants, metallurgical plants, coal washing plants, etc., the effect is good.

2. Drinking water treatment: Many water plants in China use river water as their source. The content of sand and minerals is high, and the water is relatively turbid. Although it has undergone sedimentation and filtration, it still cannot meet the requirements. Flocculants need to be added. The dosage is 1/50 of inorganic flocculants, but the effect is several times that of inorganic flocculants. For river water with serious organic pollution, inorganic flocculants and cationic polyacrylamide can be used together for better results.

3. Recovery of lost starch and distillers' grains from starch and alcohol plants: Many starch plants now have a lot of starch in their wastewater. Adding anionic polyacrylamide makes the starch particles flocculate and precipitate. Then, the sediment is pressed into cakes by a filter press and can be used as feed. The alcohol in alcohol plants can also be dehydrated and recovered by using anionic polyacrylamide for filtration.

4. Used for river sediment settling.

5. Used in the flocculation sedimentation and sludge pressing stages of papermaking water treatment. The mud cake has a low water content and good effect.

6. Used as drilling mud material. Anionic polyacrylamide has the effect of an additive, so many oil fields, geological surveys, water conservancy, and coal development choose anionic polyacrylamide because of its additive effect. Function 1: Improve the drilling speed of the drilling bit; Function 2: Reduce the bearing area of the drilling bit and protect the drilling bit; Function 3: Improve the service life of the machine drilling bit and save costs.

7. Used as a displacement agent. APAM can effectively change the fluidity and rate of newly injected water, as well as the viscosity and compatibility of equivalent liquids, greatly improving the permeability of bottom water, especially for the secondary development of petroleum. Each use of anionic polyacrylamide increases oil extraction by about 200 tons.

8. Widely used in the petroleum industry, oil extraction, drilling mud, waste mud treatment, preventing water channeling, reducing friction resistance, improving recovery rate, and tertiary oil recovery.

Example: A large amount of wastewater is produced during coal washing, and direct discharge pollutes the environment. It must be clarified and recycled, and the coal slurry in the water is also valuable. However, natural sedimentation is time-consuming and laborious, and the water is not clear.

Key words:

Anionic polyacrylamide

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products