PRODUCTS CENTER

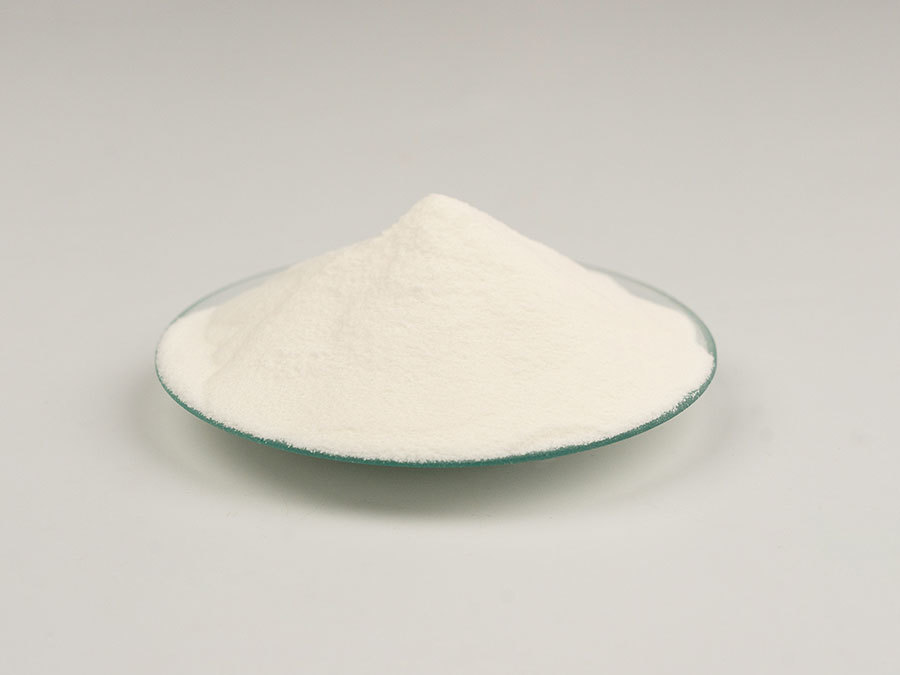

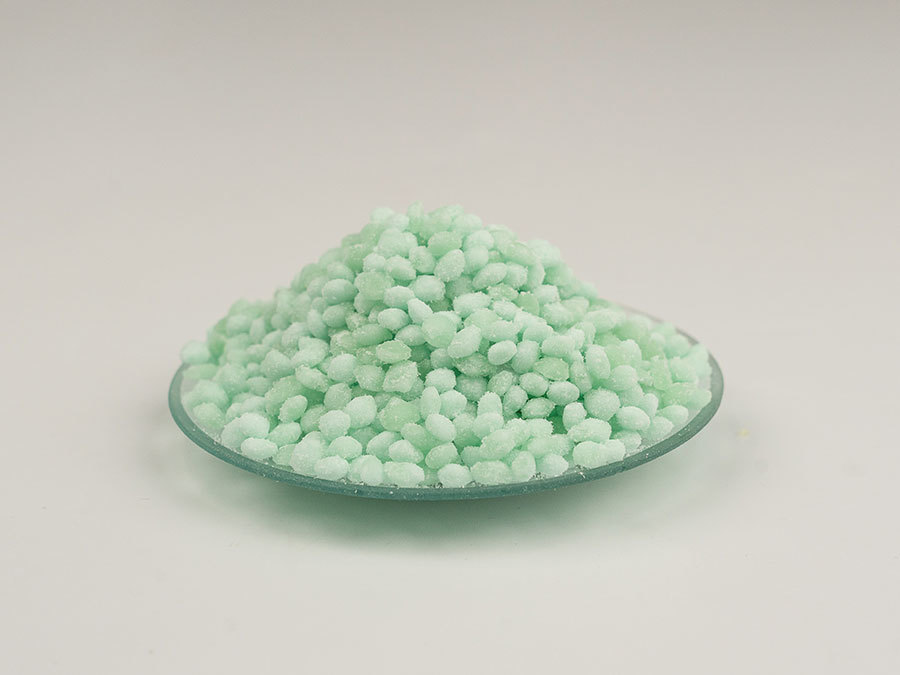

Spray-type polyaluminium chloride (National Standard 28%)

- Product Description

-

Product Introduction

This product is a new type of highly efficient inorganic coagulant, also known as polyaluminum chloride, abbreviated as polyaluminum, with the English abbreviation PAC (poly aluminum chloride). It is a water-soluble inorganic polymer between AlCI3 and Al(OH)3. This product is made from synthetic hydrochloric acid, bauxite, and calcium aluminate powder using advanced technology and has good flocculation effects. Spray drying is a method of applying systematic technology to material drying. In the drying chamber, the dilute material is atomized and the water quickly vaporizes in contact with hot air, resulting in a dried product. This method can directly dry solutions and emulsions into powder products, saving the steps of evaporation and pulverization. Through hot air drying and air conveying, the material to be dried is dispersed into very fine mist-like particles (increasing the water evaporation area and accelerating the drying process), contacting hot air, and removing most of the water in an instant, so that the solid substances in the material are dried into powder.

Product Physico-chemical Indicators

Guangrui Brand GB/T22627-2014 Industrial Grade

Indicator Name

GB/T22627-2022 Industrial Grade

National Standard

Company Standard

Aluminum oxide (as Al 2 O 3 ) mass fraction /% ≥

28

≥28.5

Basicity /%

30-98

82

Mass fraction of insolubles /% ≤

0.4

≤0.3

PH value (10g/L aqueous solution)

3.5 ~ 5.0

3.5-5.0

Mass fraction of iron (Fe) /% ≤

3.5

1.5

Mass fraction of ammonia nitrogen (in terms of N) /%

0.05

0.01

Mass fraction of arsenic (As) /% ≤

0.000 5

0.000 4

Mass fraction of lead (Pb) /% ≤

0.002

0.002

Mass fraction of cadmium (Cd) /% ≤

0.000 5

0.000 1

Mass fraction of mercury (Hd) /% ≤

0.000 05

0.000 03

Mass fraction of chromium (Cr) /% ≤

0.005

0.002

Note: The indicators of insolubles, iron, ammonia nitrogen, arsenic, lead, cadmium, mercury, and chromium listed in the table for liquid products are all calculated based on Al 2 O 3 mass fraction of 10%, when AL 2 O 3 is not equal to 10%, it should be converted to Al 2 O 3 according to the actual content and calculated based on the 10% product ratio.

Advantages of Guangrui Spray-dried Polyaluminum Chloride

1. Spray-dried polyaluminum chloride, Al 2 O 3 content is uniform and stable, and is easily controlled within the specified range. It enhances the adsorption capacity of colloidal particles, achieving both coagulation and flocculation effects, which other drying methods cannot achieve.

2. In water treatment, basicity, i.e., the degree of polymerization, directly affects the water purification effect. We use the pressure-type particle spray drying method to improve the degree of polymerization while maintaining the original activity of the mother liquor. At the same time, the basicity can be adjusted according to different water qualities. However, drum drying easily destroys the degree of polymerization, resulting in a small range of basicity and narrow adaptability to water quality.

3. Due to the use of plate and frame filter press technology, the water-insoluble solids in solids are below 0.3, and the water-insoluble solids in liquids are below 0.1, ensuring smooth pipelines for users and improving drug utilization, which cannot be achieved by natural sedimentation.

Usage

Dissolve the solid product with water at a ratio of 1:3, then dilute it with 10-30 times the amount of water to the required concentration before use. The ideal PH value for addition is 3.5-5.0. Choosing the ideal PH value for addition can maximize the coagulation effect. The dosage can be determined based on the turbidity of the raw water. Generally, when the raw water turbidity is 100-500mg/L, the dosage per thousand tons is 10-20kg. When the raw water turbidity is high, the dosage should be increased appropriately; when the turbidity is low, the dosage can be reduced appropriately.

For rural use, the agent can be added to a water tank, stirred evenly, allowed to stand, and the supernatant can be used. Add about 1 gram of this agent per 50 kg. If this agent is used in combination with the high-molecular flocculant produced by this company, the effect will be even better. For dosing, the anionic polyacrylamide or cationic polyacrylamide produced by this company can be dissolved together with PAC to form a composite flocculant, or PAC can be added to the water to be treated to form aggregates, and then the anionic polyacrylamide produced by this company can be added to adsorb and bridge to form large flocculants.

Dosage of Polyaluminum Chloride in Different Water Qualities

1. In low-turbidity water, dilute the solid polyaluminum chloride product with tap water at a ratio of 1:3 (weight ratio) and stir until completely dissolved.

2. In domestic and industrial wastewater, refer to adding about 30g of polyaluminum chloride product per ton of wastewater first. Then add the diluted polyacrylamide product (if the effect is not obvious, please adjust the amount of product added accordingly).

3. In the treatment of wastewater from paper mills, use the dosage ratio for low-turbidity water. If the effect is not obvious, it can be added in appropriate amounts.

4. When the raw water turbidity is 100-500mg/L, the dosage is 5-10mg, i.e., 5-10kg per thousand tons of water. Before use, it is recommended to conduct a small-scale test according to the water quality characteristics to select the ideal value, and then use it.

Common Wastewater Dosage Ratio

Applications

Unit: kg/1000 tons of water

Applications

Unit: kg/1000 tons of water

Domestic water

2.5~25

Industrial water

2.5~25

Urban wastewater

15~50

Electroplating wastewater

20~100

Metallurgical wastewater

20~150

Papermaking wastewater

50~300

Printing and dyeing wastewater

100~300

Bleaching and dyeing wastewater

100~300

Paint wastewater

100~300

Leather wastewater

100~300

Food wastewater

50~150

Chemical wastewater

50~100

Emulsified wastewater

50~200

Coal washing wastewater

30~100

Packaging and storage

Solids are packed in 25Kg bags, with inner plastic film and outer plastic woven bag. Products should be stored in a dry, ventilated, cool indoor place, avoid moisture, and prohibit storage with flammable, corrosive, and harmful items. (Can be processed with customer authorized packaging)

Key words:

Spray-type polyaluminium chloride (National Standard 28%)

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products