PRODUCTS CENTER

Cationic polyacrylamide

- Product Description

-

Product Introduction

Cationic polyacrylamide (CPAM) is a linear polymer compound. Due to its multiple active groups, it can interact with and adsorb many substances to form hydrogen bonds. It mainly flocculates negatively charged colloids and has functions such as clarification, decolorization, adsorption, and bonding. It is suitable for wastewater treatment with high organic colloid content in industries such as dyeing, papermaking, food, construction, metallurgy, ore dressing, coal powder, oil fields, aquatic product processing, and fermentation. It is especially suitable for dewatering treatment of urban sewage, urban sludge, papermaking sludge, and other industrial sludge.

Cationic Polyacrylamide Product Features

1. Good water solubility; it can be completely dissolved even in cold water.

2. Adding a small amount of cationic polyacrylamide product can achieve excellent flocculation effects. Generally, adding only 0.01~10ppm (0.01~10g/m3) is sufficient.

3. Using cationic polyacrylamide products and inorganic flocculants (polyferric sulfate, polyaluminium chloride, iron salts, etc.) simultaneously can yield even better results.

Product Parameters

Cationic Polyacrylamide Technical Index

CAS Number:

9003-05-8

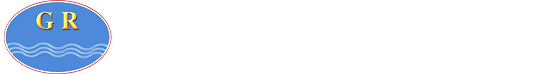

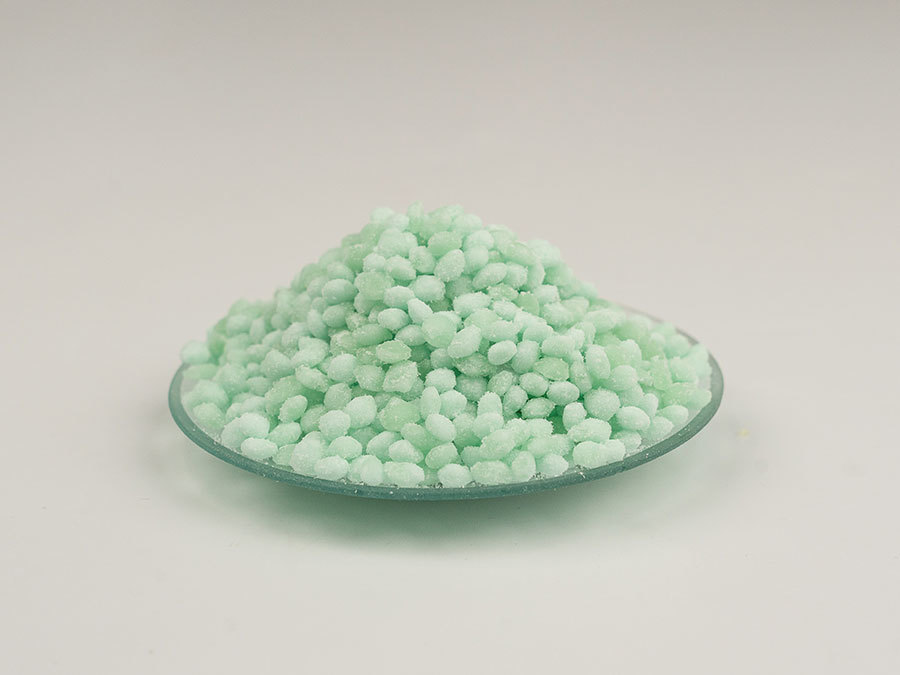

Product Appearance:

White or slightly yellow granules

Granule Size:

Granular type (20-40 mesh), fine powder type (40-60 mesh)

Molecular Weight:

3 to 12 million (adjustable)

Ionic Degree:

5-70% (adjustable)

Solid Content:

≥88-90%

Water Insoluble Matter:

≤0.02%

Dissolution Time:

≤60 minutes

Preparation Concentration:

0.1% (usually) — 0.5% (maximum)

Storage Time:

Product (2 years), prepared solution (6-30 days)

Residual Units:

≤0.1%

Applications:

For industrial use only

Cationic Polyacrylamide Applications

1. As a flocculant, it is mainly used in industrial solid-liquid separation processes, including sedimentation, clarification, concentration, and sludge dewatering. The main industries of application include: urban wastewater treatment, papermaking, food processing, petrochemical, metallurgy, ore dressing, dyeing, sugar manufacturing and various industrial wastewater treatment. Used in the sludge sedimentation and dewatering processes in urban wastewater and meat, poultry, and food processing wastewater treatment, through the positive charge groups in it to neutralize the negatively charged organic colloids in the sludge and the excellent bridging and flocculation function of the polymer, it promotes the aggregation of colloidal particles into large flocculent masses, separating them from the suspension. The effect is significant, and the dosage is small.

2. In the papermaking industry, it can be used as a dry strength agent, retention agent, and filtration aid, which can significantly improve the quality of paper, save costs, and improve the production capacity of paper mills. It can directly interact with inorganic salt ions, fibers, and other organic polymers through electrostatic bridging to enhance the physical strength of the paper, reduce the loss of fibers or fillers, accelerate water filtration, play a strengthening, retention, and filtration assisting role, and can also be used for white water treatment. At the same time, it has a significant flocculation effect during deinking.

3. In fiber slurries (asbestos-cement products), it can improve the drainage properties of the formed asbestos-cement products and increase the strength of the asbestos board blanks; in insulation boards, it can improve the binding ability of additives and fibers.

4. In the mining and coal preparation industries, it can be used as a clarifier for mine wastewater and coal washing wastewater.

5. In phosphoric acid purification, it helps separate gypsum in the wet-process phosphoric acid process.

6. Used as a water treatment flocculant in waterworks using river water sources.

Packaging and Storage of Cationic Polyacrylamide

This product is a non-toxic powder granule product and is easily affected by air, thus affecting its quality. Therefore, during storage, it should not be placed in a humid or sun-exposed environment. During loading, unloading, and transportation, contact between PAM and iron or copper metals should be avoided as much as possible. Diaphragm pumps and piston pumps are preferred for conveying pumps. The storage period for solid granules or powdered polyacrylamide is 2 years.

Key words:

Cationic polyacrylamide

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products